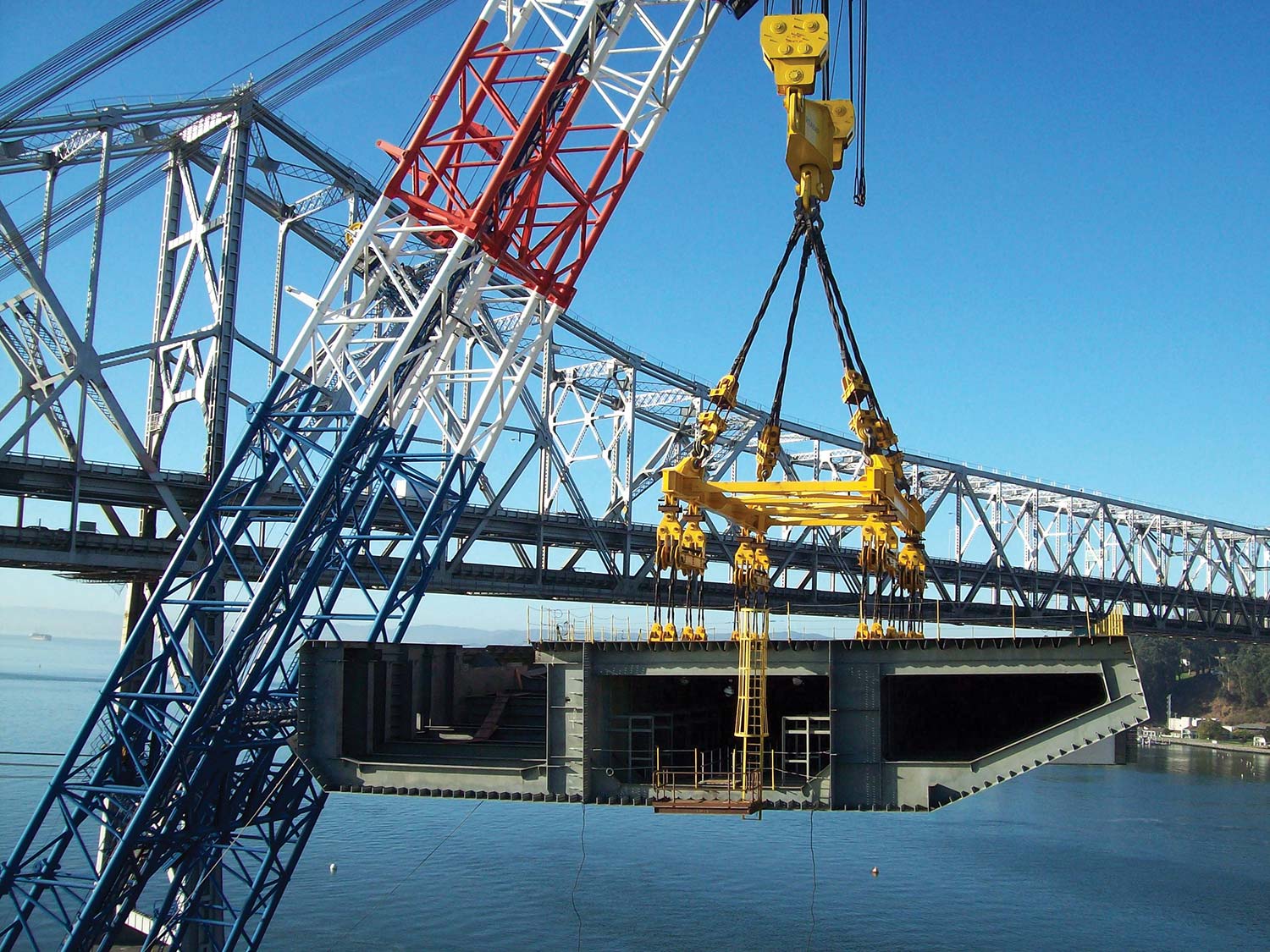

Oakland Bay Bridge

San Francisco, California

(ZPMC – 150,000 Tons of Temporary and Permanent Steel)

Fabrication Management and Quality Assurance (QA) in Asia

Ultrasonic Testing for U-ribs, PAUT Program and Other Non-Destructive Testing

Database Capture of QA Activities and Documentation for Steel Fabrication for all Asia Activities

Virtual Trial Assembly and All Survey Activities in Workshop

Construction Engineering First Kind of Structure

Shipping Logistics

Coordination of fabrication processes for over 72,000 tons of permanent steel for the tower and orthotropic box girders as well as over 40,000 tons of temporary works steel. Rosewich personnel were involved in every facet of managing the fabrication and QC/QA programs. They led the development of bespoke procedures which translated directly into ease of erection in the field because all fit-up and tolerance issues were resolved and verified in the shop prior to delivery.