Transbay Tube Internal Retrofit

San Francisco, California - Oakland, CA

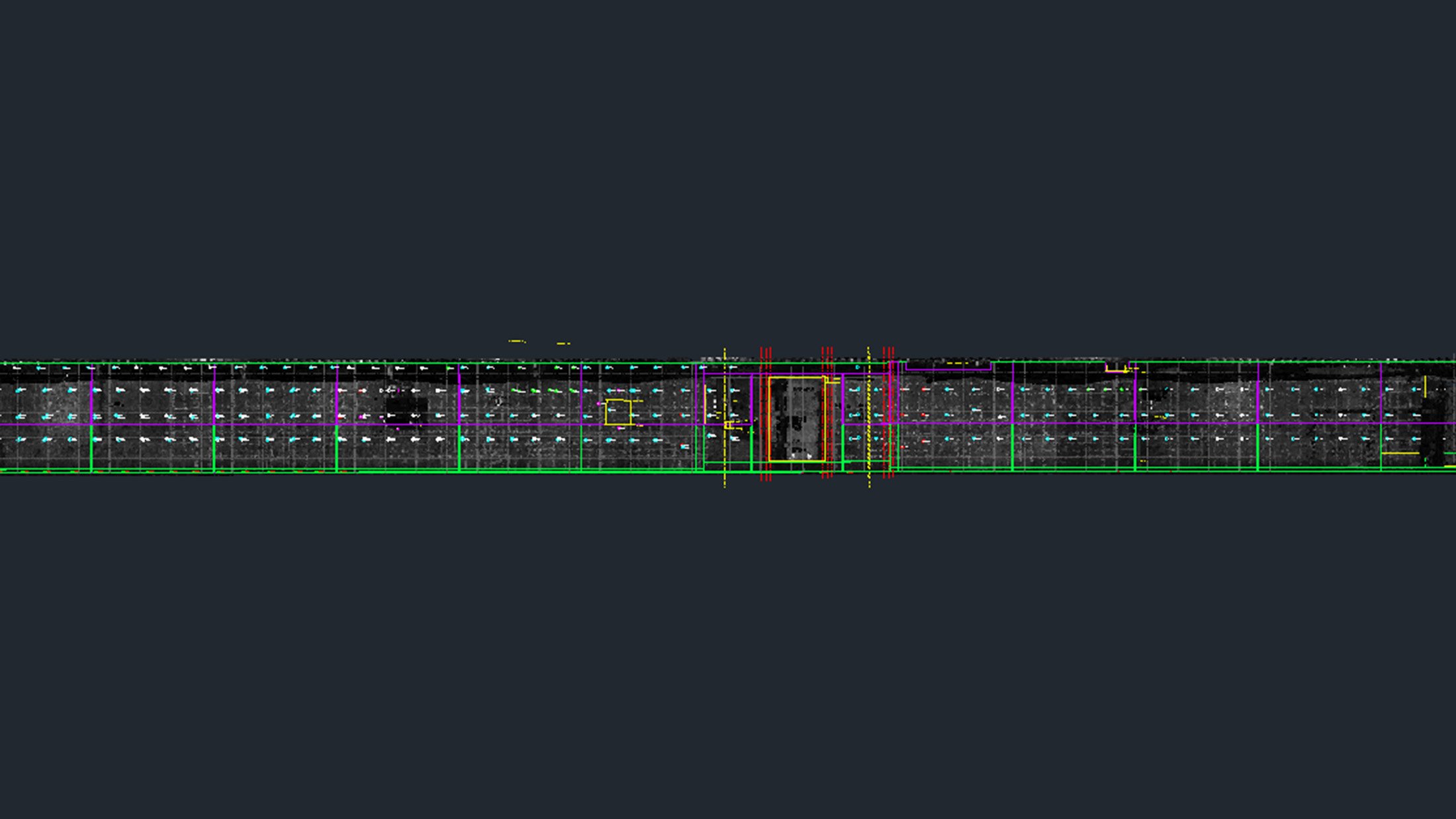

Data Analysis on Radar and Laser Scans

Statistical Analysis

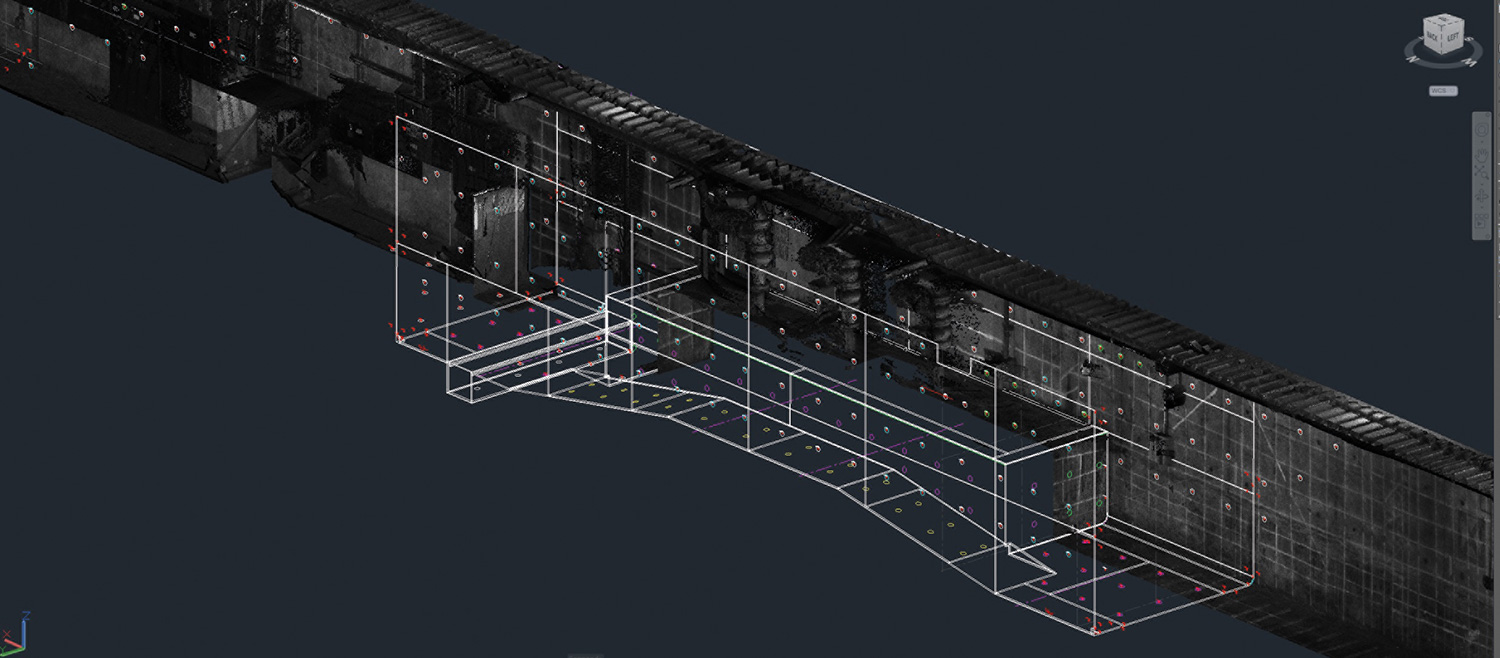

Modelling from Point Cloud and Detailing and CNC Production for Shop Assemblies

Mechanical and Electrical Coordination

Shop Survey and Layout

Rosewich was contracted to perform the structural steel detailing, which required coordinating a complex design, all on-site GPR and point cloud scanning and contractor developed erection procedures for a new steel earthquake reinforcement liner within the existing, 60 year old Bay Area Rapid Transit tunnel beneath San Francisco Bay. Detailed shop drawings were produced for over 6,000 unique panels, amounting to over 3,000 tons of steel and about 7,200 feet in length, which had to be installed – to within a quarter inch cross sectional tolerance – in a tunnel which was both horizontally and vertically curved. Advance trial assembly of each panel in the fabrication yard ensured accurate and timely installation on-site. Construction methodology included a high density point cloud scan of the tunnel and the use of ground penetrating radar to locate obstructions and all existing mechanical and electrical installations which could not be taken out of service due to the need to allow the continued running of trains through the tunnel.